We were approached by one of our customers to help them to modernize two of their rail mounted gantry cranes as their current equipment was obsolete, causing fault finding and repairs to become more troublesome.

The main body of the upgrade was a change from and S5 PLC and to an S7 PLC with associated drives.

We worked closely with our customer to minimize disruption to their work schedule and we made sure that they always had one crane available to work at any given time.

During this upgrade we came across faults that had been misunderstood on both cranes in the past due to a lack of access to the crane’s program, we rectified these faults along the way to increase reliability for the future.

The contents of this upgrade included:

Full PLC upgrade

Removal of old Siemens S5 hardware

Installation of new Siemens S7 hardware

Completely new S7 based program tailored to the crane

CMS installation (Crane Monitoring System) including new touch screens in the drivers cabin and electrical house allowing easier fault finding

Removal of old DC Drives

Installation of new DC drives including all alterations that had to be made to mount the new drives and chokes

Drive tuning and alterations tailored to the preference of the on site crane operators

Full Crane PLC and DC Drive Upgrade

Customers original DC drive

Customers original S5 PLC

New Hoist and Slew drives

New Cab CMS screen

New cab CMS screen powered up

New long travel drive

New Hoist drive and chokes

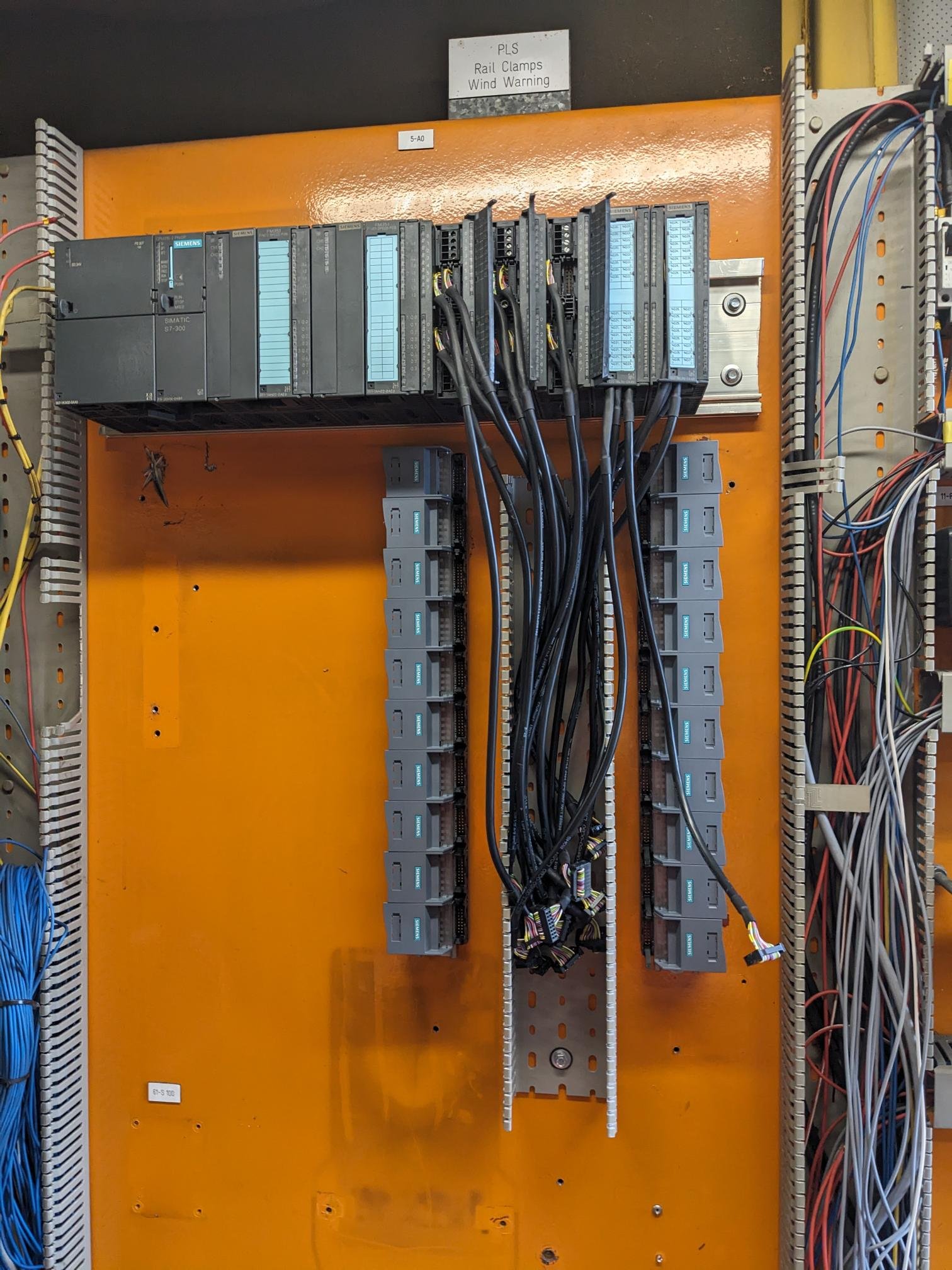

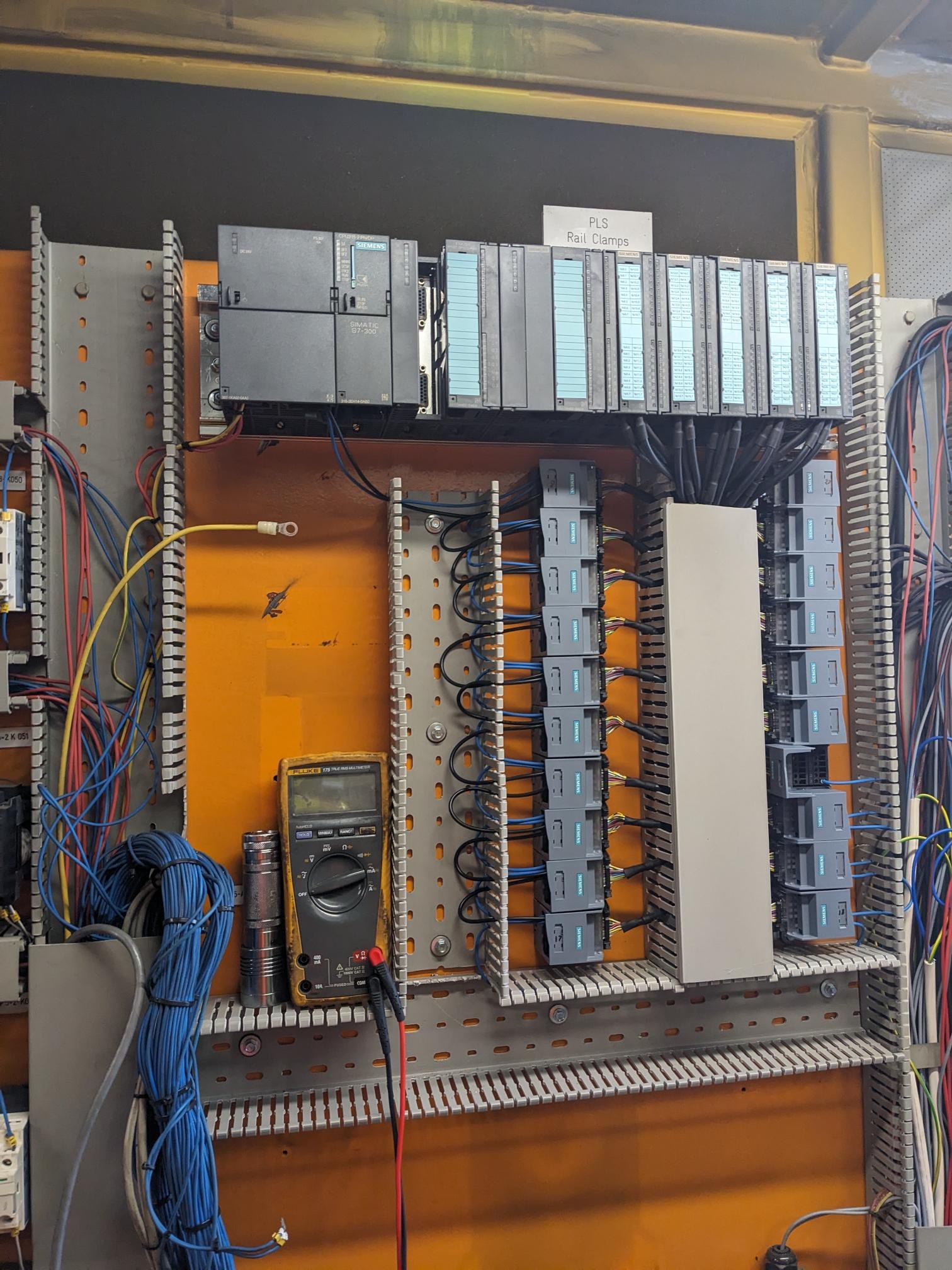

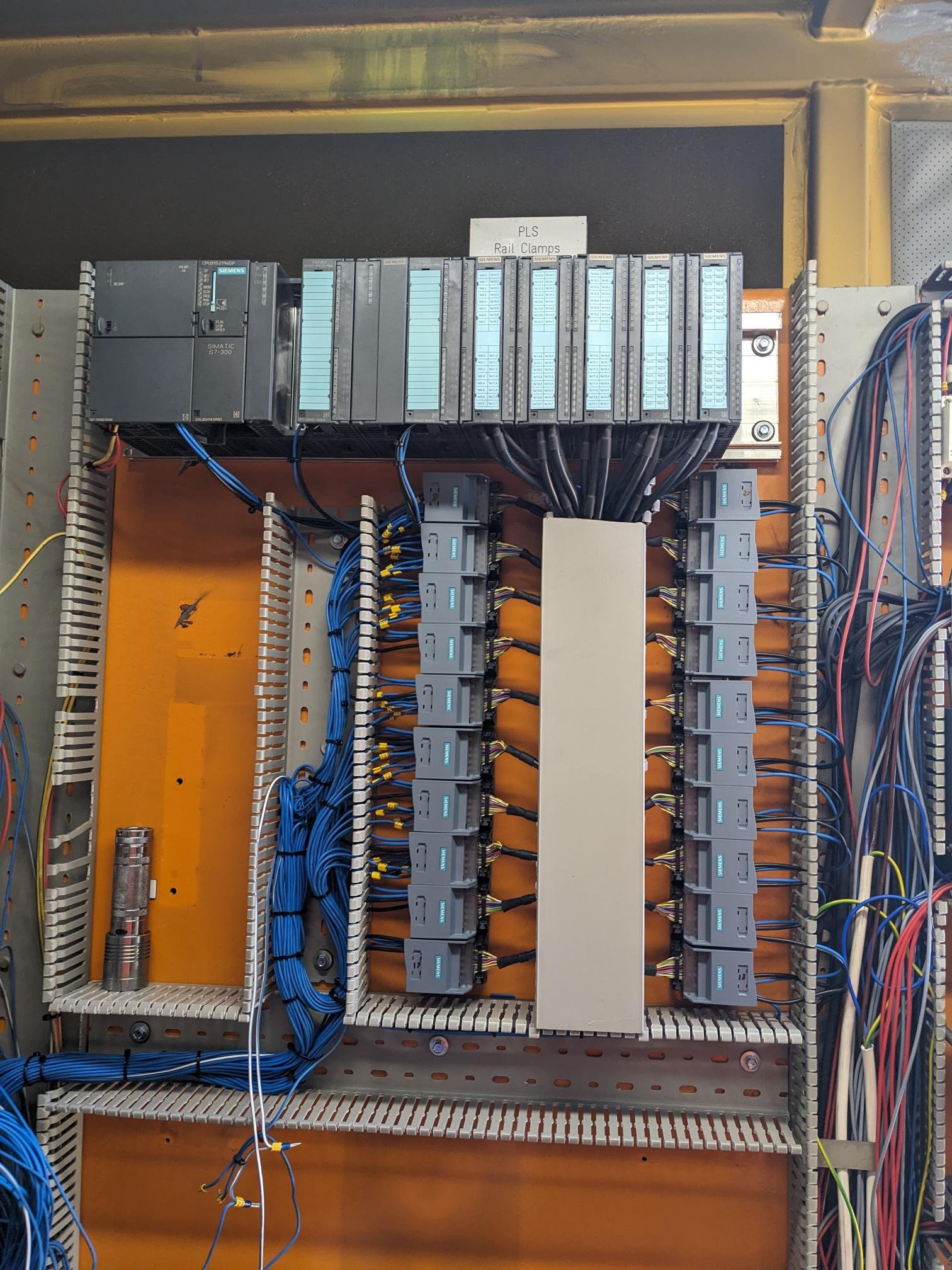

PLC install 1/4

PLC Install 2/4

PLC install 3/4

PLC install 4/4

PLC with Electrical House CMS

Overview after upgrade