All lifting equipment in the UK is governed by regulations – most notably the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) and the Provision and Use of Work Equipment Regulations 1998 (PUWER). These regulations place a duty on employers to ensure that lifting equipment is safe to use, regularly inspected and maintained.

Aftermarket safety systems are extremely important in helping organisations comply with these legal requirements, improving overall safety in lifting operations.

We supply and install a wide range of safety systems from reputable suppliers to meet the relevant safety standards.

Our engineers are qualified and competent to install and calibrate aftermarket safety systems, whether they are retrofitted to bring existing equipment up to modern safety standards, or to add additional layers of protection to cranes and general lifting equipment.

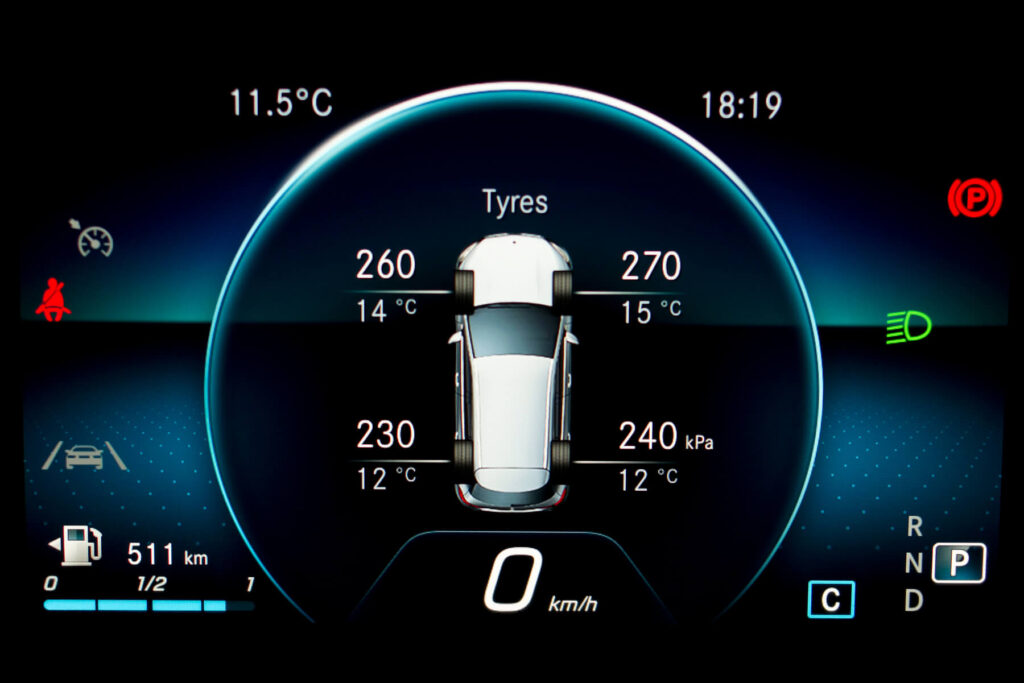

We can install systems like tyre pressure monitors and collision warning systems to any type of lifting equipment such as forklift trucks, vehicle tail lifts or towering overhead cranes.

You can depend on us to uphold the highest safety standards because we are proud to have achieved Alcumus SafeContractor accreditation, confirming that we are highly competent in all aspects of health and safety practice.

We supply and fit field-proven safety systems and devices for all kinds of overhead, gantry and jib cranes at ports, inland intermodal freight terminals, factories, construction sites and anywhere else across the UK, ensuring safety and productivity on these strategic sites.

Some examples of the crane-specific safety systems we provide are:

In simple terms these systems use sensors (radar, lasers or cameras) to detect objects and automatically slow down and stop cranes to prevent collisions.

These restrict the crane’s rotation within predefined angles, preventing the crane from entering restricted zones or colliding with obstacles.

These systems prevent the crane boom from exceeding set height or radius limits, crucial for working in areas with overhead obstructions or restricted working envelopes.

These systems continuously monitor the crane’s load, boom length, and angle to calculate the load moment and warn the operator if the safe working load is being approached or exceeded. Some systems can also prevent overloading by stopping lifting operations. These often include visual and audible alarms.

There are many more monitoring, limiting and warning devices that keep crane operations safe, preventing accidents and equipment damage.

It’s not just large, lumbering cranes that need systems to keep them operating safely. We can advise on and install a variety of safety devices and features to keep a diverse range of lifting equipment working soundly on site while protecting your personnel.

For instance we can provide you with:

Our experts are also able to fit your equipment up with a wide variety of critical safety devices like emergency stop buttons, audible and visual alarms, remote control operation, LED lighting, safety harnesses and all sorts of additional safety features.

We’re always happy to inspect your lifting equipment and advise on what is required to keep operational site and your staff safe and sound both when working at height and on the ground.